As Europe accelerates its transition to renewable energy, wind power remains a cornerstone of both national and EU-wide decarbonisation strategies. While onshore wind continues to deliver cost-effective capacity additions, offshore wind is scaling rapidly—particularly across the North Sea, Baltic Sea, and Atlantic corridors.

Although onshore and offshore wind turbines share a common architectural foundation, the design, manufacturing, and execution requirements for wind turbine components differ substantially between the two. Environmental exposure, load conditions, logistics constraints, and maintenance access all influence how components are engineered and delivered.

For OEMs, EPCs, and developers operating across both segments, understanding these differences is essential for managing risk, optimising lifecycle costs, and ensuring long-term asset reliability.

Offshore wind turbines operate in some of the most aggressive environments faced by industrial equipment in Europe. Components must withstand:

These conditions accelerate corrosion and material fatigue, placing higher demands on structural wind turbine components, electrical enclosures, and connection systems.

Onshore turbines face a different set of challenges:

While corrosion risks are lower compared to offshore, components must still be designed for long service lives and high availability, particularly in remote or mountainous regions.

Offshore wind turbine components are typically larger and heavier to accommodate higher loads and longer rotor diameters. Structural considerations include:

Nacelle housings, side covers, and canopy systems require enhanced sealing and surface protection to prevent moisture ingress and corrosion.

Onshore turbines prioritise:

Structural wind turbine components are optimised to balance strength with weight, helping reduce installation time and logistics costs.

Rotor systems—comprising blades, hub, and spinner—play a central role in energy capture for both onshore and offshore turbines.

While the core functions remain the same, material selection, protective coatings, and structural tolerances often differ between onshore and offshore applications.

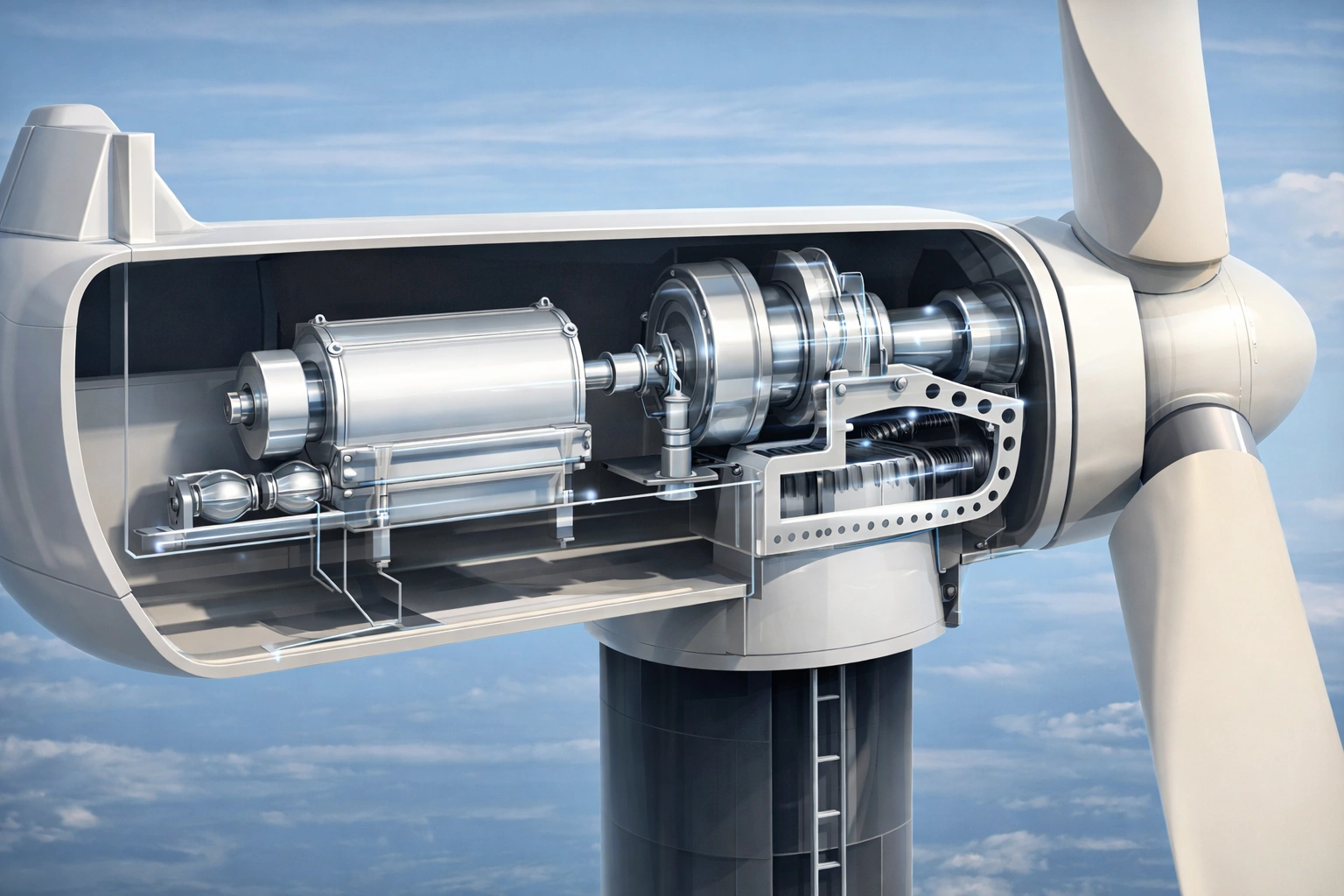

Offshore drivetrains are engineered for:

Failures offshore are significantly more costly to address, driving higher upfront investment in drivetrain robustness.

Onshore drivetrains allow for:

As a result, design trade-offs between cost and redundancy are more balanced.

Electrical wind turbine components convert mechanical energy into grid-compatible power and ensure safe, stable operation.

Offshore electrical components require:

Transformers may be located in the nacelle, tower base, or offshore substations, depending on project design. Electrical enclosures must perform reliably despite constant exposure to moisture and salt-laden air.

Onshore electrical systems emphasise:

Cable trays, connectors, and enclosures are optimised for accessibility and cost efficiency while still meeting applicable IEC and EN standards.

Offshore wind turbine components are typically:

Every hour offshore carries a high cost, making manufacturing precision and modularisation critical success factors.

Onshore projects benefit from:

Components are often delivered in smaller sections and assembled on site, allowing greater adaptability during execution.

Maintenance strategies differ significantly between onshore and offshore wind assets.

These differences influence how wind turbine components are designed, particularly in terms of:

Europe’s wind industry is increasingly focused on:

Component manufacturers supporting both onshore and offshore segments must demonstrate:

According to WindEurope, offshore wind capacity in Europe is expected to grow steadily through 2030, increasing demand for heavy structural and electrical components. The International Energy Agency also highlights offshore wind as a critical contributor to Europe’s long-term energy security.

While onshore and offshore wind turbines share core architectures, the differences in component design and execution are substantial. Environmental exposure, logistics constraints, and maintenance realities shape how wind turbine components are engineered, manufactured, and deployed across Europe.

As the region scales both onshore and offshore wind capacity, success will depend on manufacturing partners that can deliver integrated systems—combining structural, mechanical, and electrical components—with consistency, precision, and execution readiness.

1. How do offshore wind turbine components differ from onshore components?

Offshore components require enhanced corrosion protection, heavier structural design, and modular construction to support marine installation.

2. Are offshore wind turbine components more expensive?

Yes. Higher material specifications, coatings, and logistics complexity increase upfront costs, though they reduce long-term operational risk.

3. Do onshore and offshore turbines use the same electrical systems?

The core systems are similar, but offshore electrical components require higher protection ratings and more robust enclosures.

4. Why is modularisation more critical offshore?

Modular components reduce offshore assembly time, lowering installation risk and vessel costs.

5. Can one manufacturer support both onshore and offshore wind projects?

Yes, provided they have flexible fabrication capabilities and can meet differing technical and execution requirements.