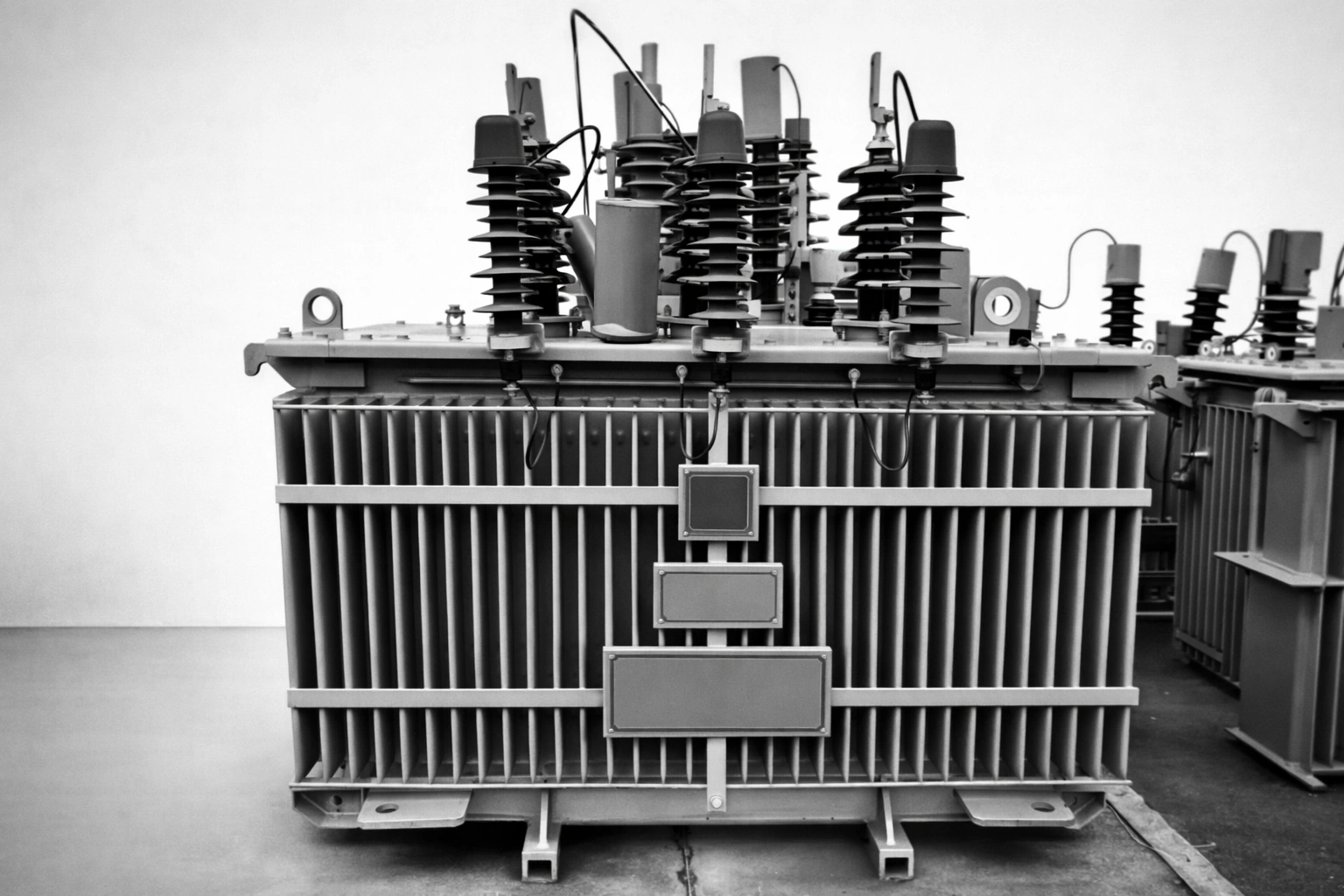

Electrical transformers are silent enablers of modern life. Every transmission line, substation, industrial facility, and renewable plant relies on transformers to move electricity safely and efficiently across voltage levels. As grid loads rise and infrastructure ages, utilities are placing renewed focus on the capabilities of electrical transformer manufacturers that design and build these critical assets.

Unlike commodity electrical equipment, transformers are long-life infrastructure investments. Utilities and EPCs expect them to operate reliably for decades under thermal stress, load fluctuations, and fault conditions. This has elevated the role of transformer manufacturers from component suppliers to long-term infrastructure partners responsible for performance, compliance, and delivery certainty.

Unimacts addresses this need through a manufacturing-led approach focused on utility-grade execution, engineering discipline, and scalable production aligned with U.S. power system requirements.

Transformers sit at every interface of the power network. Any failure—whether due to design limitations, material quality, or manufacturing inconsistency—can result in outages, safety risks, and prolonged downtime.

These pressures demand electrical transformer manufacturers capable of delivering not just nameplate ratings, but dependable performance over long service cycles.

A common misconception is that transformer selection is driven primarily by voltage class or capacity. In practice, utilities evaluate manufacturers based on how transformers are built—not just what is listed in catalogs.

Experienced electrical transformer manufacturing companies align engineering decisions closely with manufacturing realities, reducing performance variability in the field.

Although power and distribution transformers serve different grid functions, both rely on disciplined manufacturing practices.

Used in transmission and large substations, power transformers handle high voltages and fault levels. Manufacturers must carefully manage insulation coordination, thermal margins, and mechanical forces during short-circuit events.

Distribution transformers operate closer to end users and are deployed in higher volumes. Efficiency, loss optimization, and durability become the dominant design drivers.

Manufacturers that support both categories benefit utilities by simplifying supplier qualification and reducing operational complexity.

Substations increasingly operate in constrained or urban environments, driving changes in transformer design and configuration.

Substation units must deliver voltage stability and withstand continuous duty cycles. Leading substation transformer manufacturers design for reliability under varying load profiles and grid conditions.

Dry-type transformers are selected for indoor substations, commercial facilities, and locations where fire safety and reduced maintenance are critical. As dry transformer manufacturers, suppliers must optimize cooling and insulation systems without compromising electrical performance.

Beyond large power units, current transformer manufacturing supports protection, metering, and grid monitoring systems. These transformers demand precision accuracy rather than power handling.

Similarly, toroidal transformer manufacturing serves compact, low-noise applications in industrial and specialty electrical systems. These niches highlight the importance of process control and design specialization within transformer manufacturing.

A transformer manufacturing plant integrates multiple specialized processes that must operate in tight coordination.

Advanced transformer manufacturing equipment ensures consistency, but disciplined execution and quality oversight remain equally critical.

Extended transformer lead times have become a defining challenge across the industry. Utilities now assess electrical transformer manufacturers on their ability to plan production, secure materials, and manage risk across long project timelines.

Manufacturers with scalable capacity and structured execution models provide measurable advantages in:

Unimacts applies a manufacturing-first strategy to transformer production, emphasizing execution control and infrastructure-scale readiness.

This approach enables utilities and EPCs to engage with a transformer partner capable of supporting long-term grid investment rather than one-off equipment supply.

Electrical transformers are not interchangeable components—they are long-life assets that define grid reliability and operational performance. As infrastructure investment accelerates, utilities and EPCs must work with electrical transformer manufacturers that demonstrate manufacturing depth, engineering rigor, and execution discipline.

Unimacts brings a structured, manufacturing-driven approach to transformer production, supporting modern power systems with scalable capability and dependable delivery. For organizations building resilient and future-ready electrical networks, the choice of transformer manufacturer remains a strategic infrastructure decision.

1. What do electrical transformer manufacturers typically produce?

They manufacture power, distribution, substation, and current transformers used across transmission and distribution networks.

2. Why is manufacturing quality critical for transformers?

Because transformers operate continuously for decades, and manufacturing inconsistencies can lead to failures or efficiency losses.

3. Are dry-type transformers used in utility systems?

Yes. Dry-type transformers are commonly used in indoor substations and safety-sensitive environments.

4. What is the role of current transformers?

They support protection, monitoring, and metering systems within substations and industrial facilities.

5. How do utilities manage transformer lead-time risk?

By partnering with manufacturers that offer disciplined production planning and scalable capacity.