The U.S. power grid is undergoing its most significant transformation in decades. Transmission expansion, renewable energy integration, data center growth, and electrification of industrial loads are all accelerating demand for reliable, high-voltage electrical infrastructure. At the center of this evolution are transformers – critical assets that directly impact grid stability, efficiency, and long-term reliability.

As utilities and EPCs evaluate transformer manufacturers in USA, the focus has shifted beyond basic capacity. Buyers now prioritize manufacturing depth, engineering credibility, compliance readiness, and delivery assurance. Selecting the right power transformer manufacturer has become a strategic decision tied to project timelines, regulatory obligations, and lifecycle performance.

Unimacts supports U.S. power infrastructure through a manufacturing-first transformer platform designed to serve high-voltage, transmission, and utility-scale applications with global execution strength and disciplined quality systems.

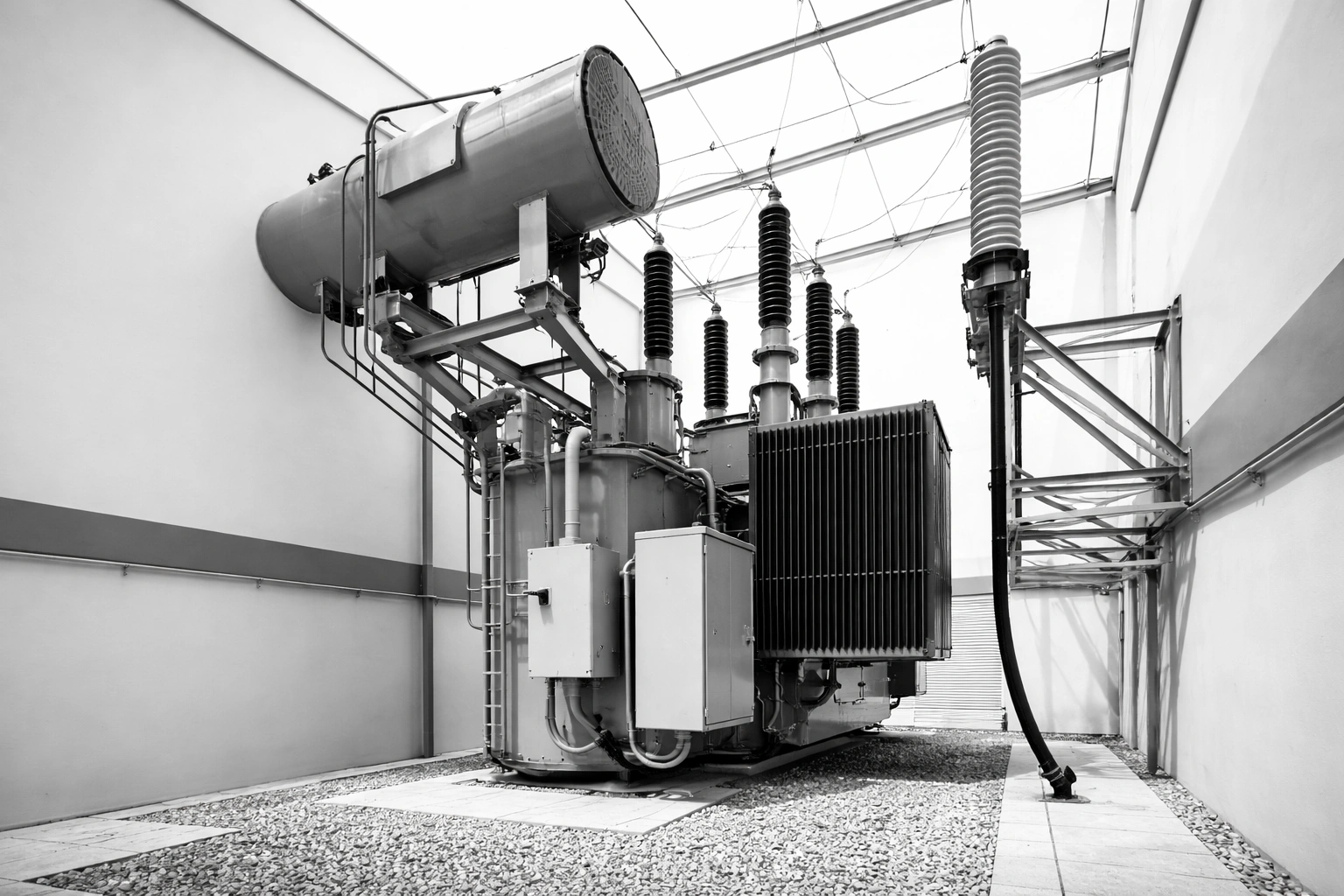

High-voltage transformers enable efficient long-distance power transmission while minimizing losses and supporting voltage stability across interconnected grids. As transmission corridors expand and renewable interconnections increase, utilities are deploying higher-capacity and more technically advanced transformer assets.

These trends are reshaping expectations from electrical transformer manufacturers, particularly those serving high-voltage applications.

Not all US transformer manufacturers are equally equipped to support high-voltage and transmission-grade requirements. Leading suppliers demonstrate strength across engineering, manufacturing, testing, and program execution.

For utilities and EPCs, these factors distinguish top transformer manufacturers from commodity suppliers.

Power transformers are essential for stepping voltages up or down across generation, transmission, and distribution networks. A capable power transformer manufacturer must combine deep engineering knowledge with scalable production.

Leading power transformer manufacturers design these units for long service life, thermal stability, and high fault tolerance—key requirements for critical infrastructure.

While high-voltage power transformers anchor transmission systems, a diversified portfolio is increasingly important.

Utilities and developers rely on 3 phase distribution transformer manufacturers to support downstream voltage transformation with efficiency and reliability.

As dry transformer manufacturers, suppliers serve indoor substations, commercial facilities, and environments where fire safety and low maintenance are priorities.

A distributed transformer manufacturer with multiple design options can better align solutions to project-specific constraints.

High-voltage manufacturing requires disciplined processes across every production stage. Leading electrical power transformer manufacturers maintain tight control over:

This end-to-end control enables predictable performance and reduces operational risk for utilities deploying long-life assets.

Unimacts operates as a globally enabled manufacturing partner supporting U.S. transformer demand across high-voltage and utility-scale applications.

This positions Unimacts alongside leading electrical transformer manufacturers serving modern grid infrastructure.

Transformer availability remains a major constraint across the industry, with high-voltage units often facing extended lead times. Utilities increasingly favor transformer manufacturers in USA and globally aligned partners that can mitigate schedule risk through diversified production and disciplined execution.

Unimacts’ manufacturing model emphasizes:

As the U.S. grid expands and modernizes, the role of transformer manufacturers in USA continues to grow in strategic importance. High-voltage applications demand more than nameplate capacity—they require engineering rigor, manufacturing discipline, and execution reliability.

Unimacts brings a manufacturing-first approach to high-voltage and utility-scale transformer programs, supporting power utilities, EPCs, and developers navigating complex grid challenges. For organizations evaluating top transformer manufacturers capable of supporting long-term infrastructure investment, Unimacts delivers the scale, quality, and operational control required for modern power systems.

1. What should utilities look for in transformer manufacturers in USA?

Engineering capability, compliance readiness, testing infrastructure, and delivery reliability are critical evaluation factors.

2. Does Unimacts manufacture power transformers for high-voltage applications?

Yes. Unimacts supports high-voltage and utility-scale power transformer manufacturing through a globally integrated production model.

3. Are dry-type transformers suitable for high-voltage environments?

Dry-type transformers are typically used for indoor or specialized applications, while oil-filled units dominate transmission systems.

4. What industries do leading electrical transformer manufacturers serve?

Utilities, renewable energy developers, EPCs, data centers, and heavy industrial facilities.5. How do transformer manufacturers manage long lead times?

Through diversified manufacturing capacity, material planning, and program-level execution discipline.