Data centers and high-density power environments are becoming the backbone of the modern digital economy. Cloud computing, AI training clusters, hyperscale platforms, fintech infrastructure, and edge computing sites all demand stable, efficient, and safe power distribution. This shift is driving a significant rise in the adoption of dry-type transformers—a category engineered for safety, reliability, and compact deployment in sensitive indoor environments.

Unlike traditional oil-filled units, dry-type transformers operate without liquid insulation, reducing fire risk, simplifying maintenance, and providing environmental advantages. As data centers grow in scale and power intensity, dry-type transformers are becoming essential components in power distribution rooms, server halls, UPS backbones, and critical power pathways.

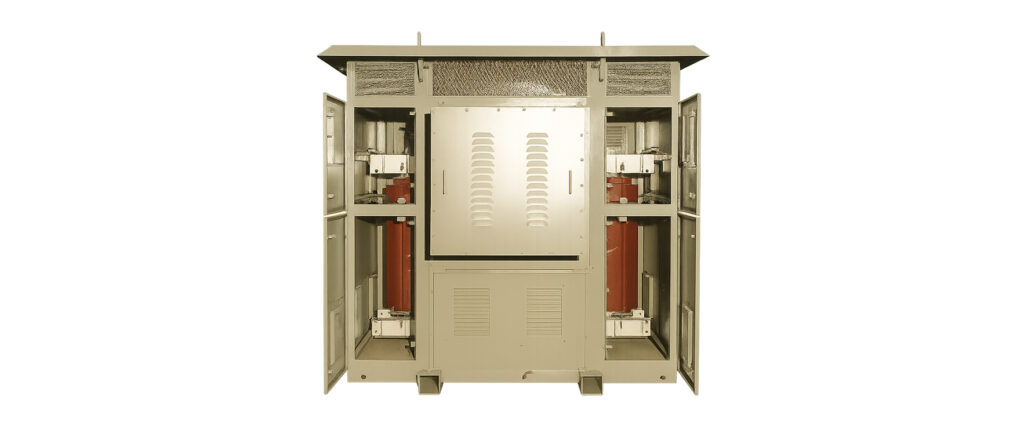

Unimacts manufactures high-reliability dry-type transformers designed for data centers, commercial buildings, industrial facilities, and dense-load environments. Strengthened by Kryfs’ 40+ years of transformer expertise and Zetwerk’s global supply-chain capabilities, Unimacts brings a future-ready, high-performance dry-type transformer offering to the U.S. market.

Modern data centers are power-intensive, high-heat environments with strict safety, space, and uptime requirements. Dry-type transformers are increasingly preferred because they align with the operational profile of such facilities.

1. Fire Safety and Risk Mitigation

Dry-type transformers use solid insulation instead of oil, drastically reducing fire hazards. This is especially critical in indoor environments where:

Data centers prioritize equipment that lowers internal fire risk—not just for compliance, but to maintain uptime.

2. Simplified Indoor Deployment

Oil-filled transformers require containment pits, fire barriers, spill mitigation systems, and separate enclosures. Dry-type units do not, making them ideal for tight mechanical rooms and multi-level data center designs.

3. Built for High-Density Loads

High-density racks, AI clusters, and HPC environments demand transformers that maintain stable performance during rapid load fluctuations.

Dry-type transformers provide:

This makes them viable for today’s AI-driven workload patterns.

4. Lower Maintenance and Operational Efficiency

Without oil filtration, leak checks, or coolant management, dry-type transformers deliver lower OPEX over their lifetime—critical for hyperscale operators focused on optimizing operational margins.

2. Dry-Type Transformers for High-Density Commercial and Industrial Applications

Beyond data centers, dry-type transformers are experiencing rising adoption in:

These locations prioritize safety, uptime, and environmental performance—making dry-type designs the ideal choice.

Dry-type transformers deliver strong performance across:

Unimacts’ dry-type transformers are engineered to meet these high-demand operational standards through robust insulation systems and optimized thermal design.

3. How Unimacts Supports the Demand for Dry-Type Transformers

Unimacts manufactures dry-type transformers across its advanced global production network. Facilities in India, Oman, and the UAE enable the complete manufacturing workflow—from core cutting to winding to assembly and testing—creating a fully controlled, high-quality production pipeline.

1. Global Manufacturing Capabilities

Unimacts’ transformers facilities support key processes including:

These capabilities allow Unimacts to tailor transformer solutions to specific data center and industrial requirements.

2. U.S. Market Presence and Execution Strength

Based in Sloan, Nevada—with products installed across four continents and over $1B delivered to U.S. customers—Unimacts provides deep engagement with data center developers, hyperscale operators, and commercial EPCs.

3. Supply Chain Scale Through Zetwerk

Zetwerk’s global network supports:

This ensures stable lead times and cost efficiency.

4. Engineering Backbone Through Kryfs

Kryfs strengthens Unimacts with:

This technical depth reinforces Unimacts’ credibility in delivering dry-type transformers for mission-critical environments.

4. Performance Characteristics of Unimacts’ Dry-Type Transformers

Unimacts’ dry-type transformers are engineered to deliver robust performance in high-density, mission-critical, and indoor environments.

1. High Thermal Performance

Dry-type insulation systems built for elevated ambient temperatures make them ideal for server rooms and mechanical spaces.

2. Superior Short-Circuit Strength

Reinforced windings and structural integrity ensure stability under high fault currents typical in large data center electrical architectures.

3. Harmonic-Resistant Design

Data centers and industrial systems with VFDs, UPS systems, and nonlinear loads benefit from transformers engineered to handle harmonic distortion without excessive heating.

4. Noise Reduction

Core design and winding geometry reduce audible noise—important for indoor and mixed-use buildings.

5. Compact Footprint

Dry-type units eliminate the need for containment pits or fire-rated oil rooms, enabling more flexible architectural layouts.

These capabilities align with Unimacts’ broader transformer portfolio, which spans distribution, power, pad-mounted, inverter-duty, and oil-filled designs.

5. Meeting U.S. Data Center Growth and Reliability Requirements

The United States is witnessing explosive growth in data center construction driven by:

Transformers are mission-critical equipment controlling power availability, distribution efficiency, and facility safety.

1. Faster Lead Times

Unimacts delivers transformers in 18–24 months, compared to the industry’s 30–36 month norm.

This is essential for developers racing to commission facilities quickly.

2. Multi-Continent Manufacturing Redundancy

Facilities across India, Oman, and UAE ensure:

3. Quality and Compliance Assurance

Routine and type testing ensure alignment with:

All supported by Unimacts’ mature manufacturing infrastructure.

6. Why Dry-Type Transformers Will Continue to Rise in High-Density Applications

The shift toward dry-type transformers will accelerate due to:

Data centers, in particular, will rely more heavily on dry-type units due to their unique combination of safety, scalability, and performance.

Unimacts, supported by Kryfs’ engineering legacy and Zetwerk’s global network, is positioned as a strategic supplier driving this next phase of power infrastructure evolution.

Dry-type transformers are becoming a cornerstone of modern data center and high-density power architecture. Their inherent safety, low-maintenance operation, environmental advantages, and robust thermal performance make them ideal for mission-critical environments.

Unimacts manufactures high-performance dry-type transformers through a globally integrated network, strengthened by:

As digital infrastructure expands, Unimacts stands ready to support the next generation of high-density power systems with reliable, future-ready dry-type transformer solutions.

Partner with Unimacts for high-reliability dry-type transformers built for data centers and high-density applications. Leverage our global manufacturing strength and U.S. support for fast, reliable execution. Contact us to scope your next requirement.

1. Why are dry-type transformers ideal for data centers?

They offer fire safety, compact footprint, high thermal performance, and low maintenance—critical for indoor, high-density environments.

2. Does Unimacts manufacture dry-type transformers?

Yes. Unimacts manufactures dry-type transformers through its global network in India, Oman, and UAE, supported by strong U.S. operations.

3. How does Kryfs strengthen Unimacts’ capabilities?

Kryfs provides 40+ years of transformer expertise, CRGO core leadership, and Tier-1 utility approvals, enhancing engineering depth and reliability.

4. Which industries benefit from dry-type transformers?

Data centers, semiconductor fabs, hospitals, airports, commercial buildings, industrial automation, and clean-room environments.