Utility-scale renewable projects—whether large solar PV installations or grid-tied battery energy storage systems (BESS)—depend on equipment designed specifically for the operational realities of modern clean energy generation. While traditional transformers have historically supported grid infrastructure, the rise of inverter-based resources introduces new electrical conditions that require specialized transformer engineering.

This is where inverter-duty transformers become indispensable.

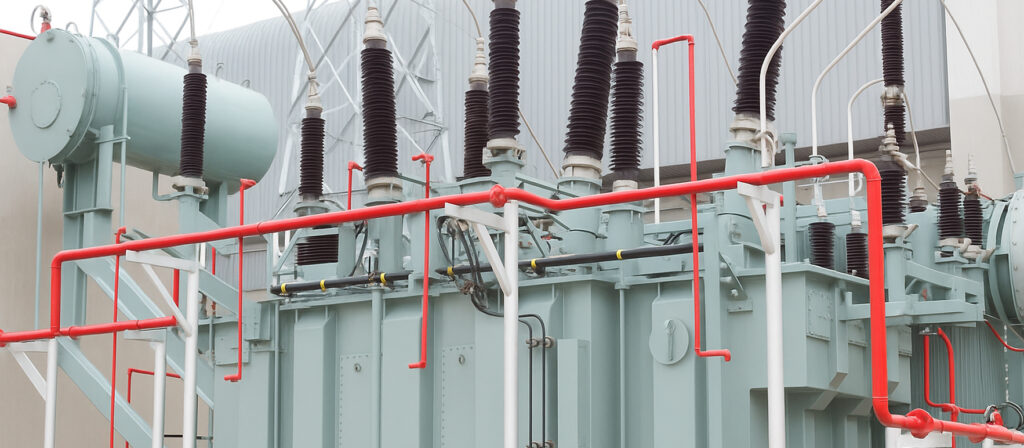

Inverter-duty transformers are engineered to withstand high harmonic currents, rapid cycling, non-linear loads, and transient conditions characteristic of solar and storage assets. Without these specialized transformers, renewable plants struggle with overheating, efficiency losses, insulation degradation, and grid non-compliance.

Unimacts, strengthened by Kryfs’ 40+ years of transformer expertise and backed by Zetwerk’s global supply-chain ecosystem, manufactures high-reliability inverter-duty transformers purpose-built for utility-scale renewable deployments. This unified model allows Unimacts to serve utilities, developers, and EPCs with dependable performance, consistent quality, and accelerated delivery timelines.

This blog explores why inverter-duty transformers are essential to solar and BESS projects—and how Unimacts’ global manufacturing capabilities uniquely position the company as a reliable partner in America’s renewable energy transition.

Utility-scale solar and BESS deployments operate through sophisticated power electronics rather than conventional synchronous generators. The output from solar inverters and battery inverters contains:

Traditional transformers are not designed for these conditions. They experience:

Inverter-duty transformers manufactured by Unimacts are engineered to handle these harmonic-rich signals through:

These design enhancements provide stable, reliable operation even under heavy renewable generation stress.

Unimacts’ capabilities are strengthened by the transformer engineering heritage of Kryfs, which brings decades of CRGO core expertise and global utility approvals. This synergy ensures every Unimacts transformer is designed to perform under the electrical realities of modern renewable systems.

Unlike steady industrial or utility loads, solar and BESS systems fluctuate unpredictably based on:

This constant variability imposes significant thermal and electrical stress.

Renewable assets frequently operate in:

Conventional transformers struggle with this operational rhythm.

Unimacts manufactures inverter-duty transformers designed to withstand renewable cycling without compromising performance or lifespan. This includes:

These capabilities are enabled through Unimacts’ global manufacturing network across India, Oman, and UAE, which includes integrated winding, core fabrication, tank construction, and full-scale testing.

Renewable energy assets must comply with increasingly strict grid codes and interconnection requirements, including:

Inverter-duty transformers play a core role in ensuring:

Each Unimacts transformer goes through comprehensive routine and type testing at globally recognized facilities, ensuring compliance with international standards. This includes:

Advanced production systems—including CRGO core processing, winding, assembly, and validation—underpin Unimacts’ ability to manufacture grid-compliant units at scale.

Renewable project sites often exist in challenging environments such as:

Inverter-duty transformers must be engineered to operate reliably under these conditions.

Unimacts manufactures transformers with:

These capabilities are supported by Unimacts’ extensive renewable-sector manufacturing experience across solar modules, tracker components, torque tubes, foundations, and global project deployments.

This cross-industry maturity reinforces transformer reliability in harsh renewable environments.

One of the largest barriers to renewable project execution is transformer lead time.

Industry norms often exceed 30–36 months, delaying project schedules and interconnection timelines.

Unimacts delivers transformers in:

Unimacts also supports IRS safe-harbor timelines, enabling delivery of critical components (such as structural fabrications) within 45 days to qualify renewable projects for tax incentives.

This combination of delivery agility and supply-chain resilience makes Unimacts a high-value partner for developers and EPCs navigating time-sensitive renewable deployments.

A central pillar of Unimacts’ inverter-duty transformer capabilities is Kryfs, one of India’s most respected transformer manufacturers.

Kryfs’ deep technical expertise gives Unimacts the engineering rigor and manufacturing credibility required to deliver inverter-duty transformers that meet exacting U.S. renewable standards.

This strategic strength positions Unimacts as a unified, globally competitive transformer manufacturer for the renewable sector.

The rapid growth of utility-scale solar and BESS is reshaping America’s grid. As renewable integration increases, inverter-duty transformers have become essential assets—supporting harmonics management, thermal stability, reliability, and grid compliance.

Unimacts stands at the center of this evolution with a manufacturing-first model strengthened by:

Unimacts delivers high-performance inverter-duty transformers that match the pace, scale, and reliability expectations of the U.S. renewable industry.

Partner with Unimacts for high-reliability inverter-duty transformers engineered for utility-scale solar and BESS projects. Leverage our global manufacturing strength and strong U.S. presence to accelerate execution. Contact us to scope your next requirement.

1. Why do utility-scale renewables require inverter-duty transformers?

Because solar and BESS generate harmonics, rapid cycling, and non-linear loads that conventional transformers cannot handle safely or efficiently.

2. Does Unimacts manufacture inverter-duty transformers?

Yes. Unimacts manufactures inverter-duty transformers through its global network in India, Oman, and UAE, supported by strong U.S. operations.

3. What makes Unimacts a reliable partner for renewable developers?

Accelerated with fast lead times, deep transformer engineering heritage via Kryfs, and global supply-chain stability powered by Zetwerk.

4. Does Unimacts support IRS safe-harbor requirements?

Yes. Unimacts can supply essential components within 45 days to support safe-harbor tax credit qualification.

5. Which renewable applications does Unimacts support?

Utility-scale solar, solar+storage hybrid systems, grid-tied BESS, and high-capacity inverter stations.